Jiangsu Shenjiang Environmental Technology Co., Ltd.

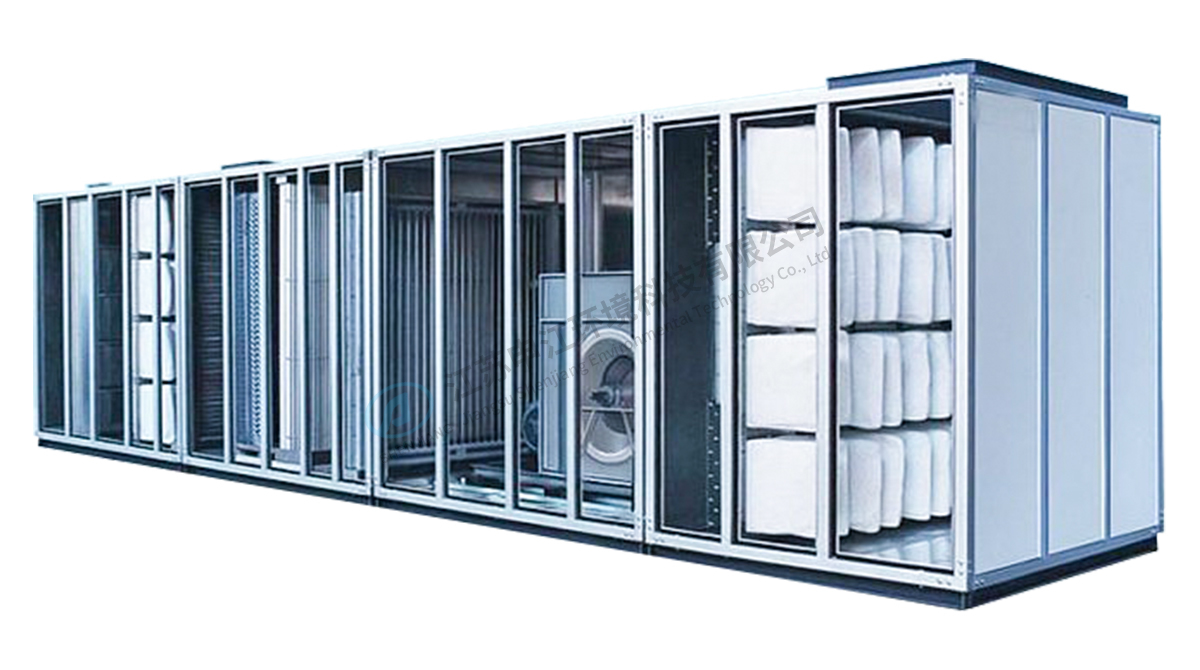

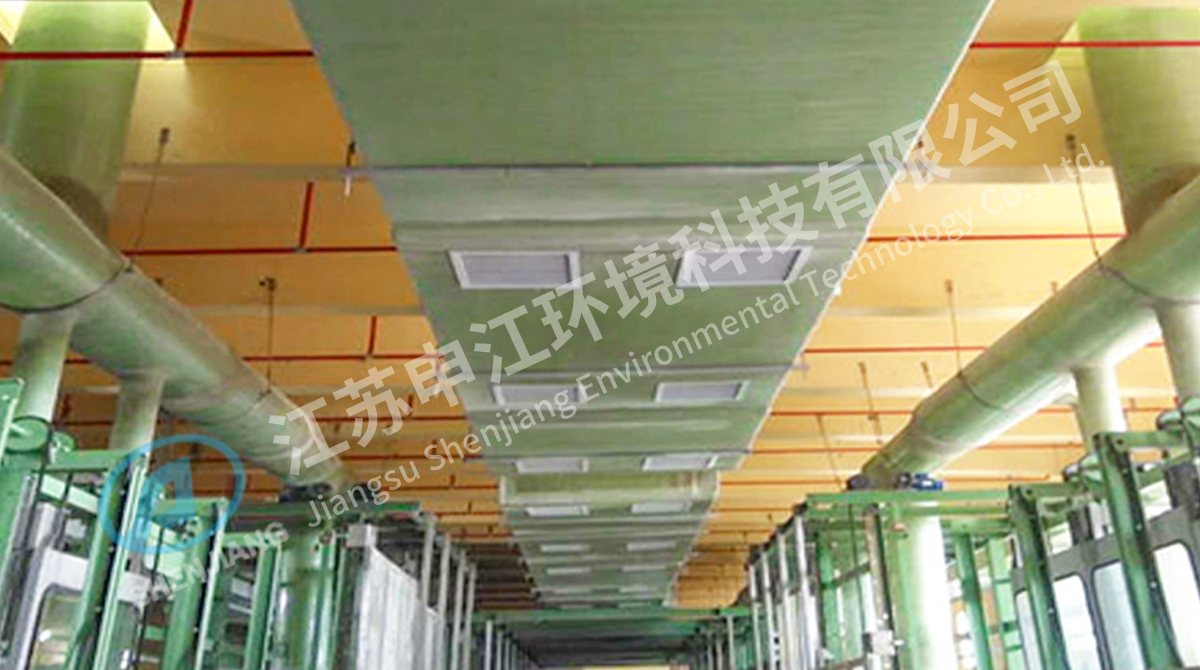

Didirikan pada tahun 1996, Jiangsu Shenjiang Environmental Technology Co., Ltd.adalah perusahaan profesional Cina Menara Pendingin Produsen dan Menara Pendingin Pabrik.Terletak di kota Yancheng yang indah, Provinsi Jiangsu, yang dikenal dengan julukan "Negeri Air dan Ikan-Nasi". Perusahaan ini berspesialisasi dalam merancang, mengembangkan, memproduksi, dan memasang set lengkap peralatan pengolahan gas buang dan produk material komposit berbasis resin. Berpegang pada prinsip "orientasi pasar dan inovasi teknologi", kami teguh dalam inovasi ilmiah dan teknologi, memastikan pertumbuhan perusahaan yang berkelanjutan dan stabil. Tim kami terdiri dari 218 karyawan yang berdedikasi, termasuk 35 teknisi profesional, dan kami dilengkapi dengan lebih dari 100 mesin pengujian dan produksi canggih. Pusat Litbang kami seluas 3.000 meter persegi, sementara bangunan pabrik, gedung perkantoran, dan gedung bisnis kami meliputi area seluas 35.000 meter persegi. Dengan modal terdaftar sebesar 101,6 juta yuan dan total aset sebesar 154 juta yuan, kami telah berkembang selama dua dekade melalui inovasi mandiri yang berkelanjutan, memanfaatkan material, teknologi, dan proses baru, yang menghasilkan klaster industri dengan beragam paten. Shenjiang menerapkan pendekatan yang beragam dan multifaset untuk integrasi industri-akademisi. Kami mengadopsi model pelatihan terapan yang menggabungkan riset teoretis dengan eksplorasi praktis, membangun hubungan kerja sama jangka panjang dengan institusi-institusi terkemuka seperti Universitas Tenggara, Universitas Sains dan Teknologi Shanghai, Universitas Xi'an Jiaotong, "Pusat Penelitian Teknologi Basis Industri Peralatan Perlindungan Lingkungan Tiongkok," dan "Pusat Penelitian Teknologi Rekayasa Pengendalian Pencemaran dan Pemanfaatan Sumber Daya Jiangsu." Selain itu, kami secara aktif mempromosikan kerja sama ilmiah dan teknologi internasional, menjalin kemitraan dengan negara-negara seperti Indonesia, Thailand, Austria, dan Singapura. Dipandu oleh filosofi bisnis "teknologi, kredibilitas, layanan, dan pengembangan," kami telah mengembangkan serangkaian produk inovatif termasuk sistem pengolahan dan pemulihan gas buang, sistem desulfurisasi dan denitrifikasi, sistem dan fitting unit pendingin udara sentral, pipa angin, pipa komposit berbasis resin, pipa sandwich pasokan dan drainase air, peralatan non-standar dan tangki penyimpanan material komposit berbasis resin, menara pendingin, peralatan non-standar serat kimia, peralatan tungku pembersih, dan pengecatan set lengkap peralatan. Proses-proses baru ini dicirikan oleh teknologi canggih, adaptabilitas yang kuat, pengoperasian yang sederhana, dan biaya rendah. Kami telah mengantongi 40 sertifikasi teknologi hak milik, dengan 30 sertifikasi utilitas, 4 sertifikasi penemuan, dan 7 sertifikasi PCT. Perangkat pemulihan dan pengolahan gas buang yang kami kembangkan secara independen telah terdaftar dalam "Katalog Teknologi Baru dan Produk Baru Unggulan Provinsi Jiangsu". Dengan kehadiran global, kami telah mendirikan kantor pasokan, instalasi, dan penjualan di berbagai lokasi, termasuk Indonesia, Singapura, Austria, Xinjiang, Fujian, Nanjing, Shandong, dan Sichuan. Selain itu, kami memiliki tim konstruksi profesional yang berspesialisasi dalam perlindungan lingkungan, mekanikal dan elektrikal, serta instalasi peralatan anti-korosi dan insulasi. Seiring pertumbuhan perusahaan kami, Shenjiang berkomitmen untuk meningkatkan pengaruh mereknya, bersatu menghadapi tantangan, dan mengupayakan pengembangan bersama untuk masa depan bersama. Kami menganut pendekatan yang berorientasi pada manusia dan filosofi pengembangan yang menekankan inovasi ilmiah. Dengan persatuan dan tekad untuk mengatasi kesulitan, kami mempertahankan semangat kewirausahaan dan komitmen teguh terhadap prinsip-prinsip pendirian kami. Kami berupaya menciptakan kekayaan intelektual bagi perusahaan kami, secara bertahap mengalihkan fokus ke bisnis inti, dan mengejar pengembangan yang terdiversifikasi. Kami terus berinovasi dan bertransformasi, mengikuti tren perkembangan pasar domestik dan internasional, serta bertujuan untuk membangun proyek-proyek baru dan mencapai hasil-hasil baru. Kami berdedikasi untuk memberikan kontribusi yang lebih besar bagi pelestarian lingkungan..

Bahasa Indonesia

Bahasa Indonesia  中文简体

中文简体 Español

Español عربى

عربى русский

русский ไทย

ไทย bahasa Indonesia

bahasa Indonesia Tiếng Việt

Tiếng Việt